What are the different Stainless steel finishes? A comprehensive guide

Stainless steel is not only versatile with various different grades and compositions, but also in its surface finishes. You may be aware of “mirror finish” and “mill finish”, but how exactly are these finishes achieved? It’s not as simple as you may think! Knowledge of Stainless steel finishes is vital for not only the aesthetic application of your Stainless, but also its intended use, as finishes and polishes are important to take into consideration for many industrial applications. Furthermore, corrosion resistance can be significantly impacted by sub-optimal surface finish selection.

See below an in depth guide on how Stainless steel finishes are achieved, what we stock at Stirlings as well as end uses.

Terminology guide

Hot rolling and Cold rolling

Hot rolled steel:

Often called Plate, steel that has been roll-pressed at very high temperatures, making it easier to work with. The high temperatures result in a scaly surface and less precise dimensions as the steel shrinks as it cools, therefore it is often used in applications where minutely specific dimensions aren’t crucial. Hot rolled products are generally further processed, or use “as-is” for non-aesthetically demanding applications.

Cold rolled steel:

Often called Sheet, this is essentially hot rolled steel that has been undergone further processing. Once hot rolled steel has cooled, it is then re-rolled at room temperature to achieve more exact dimensions and better surface qualities, resulting in a superior finish, and more precise measurements compared with hot rolled steel.

When produced in a cold worked condition rather than annealed post cold rolling, it is also typically harder and stronger, as the metal is shaped at the lower temperatures, the steel’s hardness, resistance against tension breaking, and resistance against deformation are all increased due to work hardening. Refer to ASTM A666 for further detail.

Note there is a limit to the thicknesses cold rolled sheet is produced. Capabilities vary by mill, however 3-4mm is generally where the transition from CR sheet to HR plate occurs.

Annealing

Annealing is an important process where the material, when heated to around 1050˚C, is able to reach its most relaxed state, eliminating internal stresses which hinder formability. A rapid quench down to room temperature “locks in” this condition.

Pickling

Pickling is the removal of high temperature scale and low-chromium areas near the surface, using strong acids such as nitric or hydrofluoric. These typically occur during welding or fabrication, and are important to remove to allow the surface to re-establish a passive, corrosion resistant state.

Passivation

Passivation is the treatment of the surface of Stainless steels, often with acid solutions (or pastes), to remove contaminants and promote the formation of the passive film on a freshly created surface (e.g. through grinding, machining or mechanical damage).

Common passivation treatments include nitric acid (HNO₃) solutions or pastes which will clean the steel surface of free iron contaminants. Passivation will also aid in the rapid development of the passive oxide film on the steel's surface. Passivation does not usually result in a marked change in appearance of the steel surface.

Grit

ANSI B74.12 defines the size distribution of particles allowed to be contained in a certain “grit” of abrasive. Grit is therefore not a designation of specific particle size, but a description of a specific distribution of particle sizes. For example ANSI B74.12 specifies that to be considered a 100 grit abrasive all the material must pass through a standard 70 screen with a maximum of 20% of the material being retained on a standard 100 screen. This means that up to 20 percent of the material is larger (more coarse) than the standard 100 screen opening while, at least 80% is smaller (finer) than the standard 100 screen opening. This wide distribution of particle size means that scratch patterns will be inconsistent, with larger particles leaving deeper scratches and finer particles leaving shallow scratches. This varied scratch pattern must be able to be removed by the next abrasive used.

In short, as the grit number increases, the more fine particles will be present, which will lead to more shallow scratches and therefore a more polished surface.

Polish

Polishing is used to remove surface oxidation, enhance the appearance of metal, create a reflective surface, and prevent corrosion. Polishing evens out the surface of the metal by using abrasive belts or discs to remove pits, scratches, and mill scale. Polishing produces a lined or brushed finish with visible grit lines that vary depending on the abrasive used.

Buffing

Buffing is performed using a rotating cloth wheel or mops with fine abrasive polishing compound to achieve a variety of finishes most appropriate for the intended application. Buffing is often performed after a refinement polish to remove grit lines and create a bright lustre finish.

Sheet Finishes

Non-abrasive finishes

Refers to Stainless steel finishes achieved through non-abrasive means, such as heating, cooling and addition of certain acids or other solutions. These can be the final result or can be a starting point of the Stainless steel surface to be finished with a mechanical polish (abrasive).

Non-abrasive finishes available at Stirlings:

NO. 2B FINISH

The No. 2B Finish involves:

Hot rolling,

Cold rolling,

Annealing,

Pickling,

Very lightly rolling once more on polished rolls.

The end result is a surface that is smooth and moderately reflective. It is a popular choice in various applications, frequently found on kitchen appliances, in equipment used for dairy, food, and beverage processing, and certain architectural elements.

Electrolytically coloured finishes are produced by using an electrolytic process that deposits a thin layer of oxide onto the surface, refracting light and producing different colours depending on the thickness of the oxide layer. It manipulates the natural oxide layer's properties to achieve the desired hue. This finish is often chosen for decorative or architectural applications for its unique appearance.

Etched or patterned finishes are created by using chemical solutions or acids to selectively remove areas of the metal surface. This process results in visible patterns, designs, or textures. This finish is often used for decorative purposes, signage, or to improve grip in functional applications.

Other chemical Stainless steel finishes:

MILL FINISH or NO 1 FINISH

Both terms tend to be used interchangeably, but ultimately both are mill finishes representing the unpolished and unabraded surface as it comes directly from the manufacturing mill. It can serve as a starting point for further finishes or treatments, depending on the desired end-use, but is typically the as-supplied form for hot rolled plate, profiles and many other products.

NO. 2D FINISH

The No. 2D Finish is very similar to the 2B finish, differing in its “duller” lustre. It has gained popularity where low reflectivity is specified, such as civil applications like building claddings.

BRIGHT ANNEALED (BA) FINISH

Bright Annealed (BA) Finish, a smooth and highly reflective mirror-like finish, is achieved by annealing in an oxygen-free environment, which prevents any discoloration or oxidation on the surface. Often used for decorative or aesthetic purposes, such as in kitchen appliances, architectural panels, and some automotive parts. This finish is generally specified for Sheets as well as Tubes.

Mechanically polished finishes

A mechanically polished finish is achieved by physically grinding, buffing, or polishing the metal surface using abrasives. This process smoothens the surface and can produce a range of finishes, from matte to mirror-like, depending on the grit size of the abrasive used and the polishing steps taken.

Mechanically polished finishes available at Stirlings:

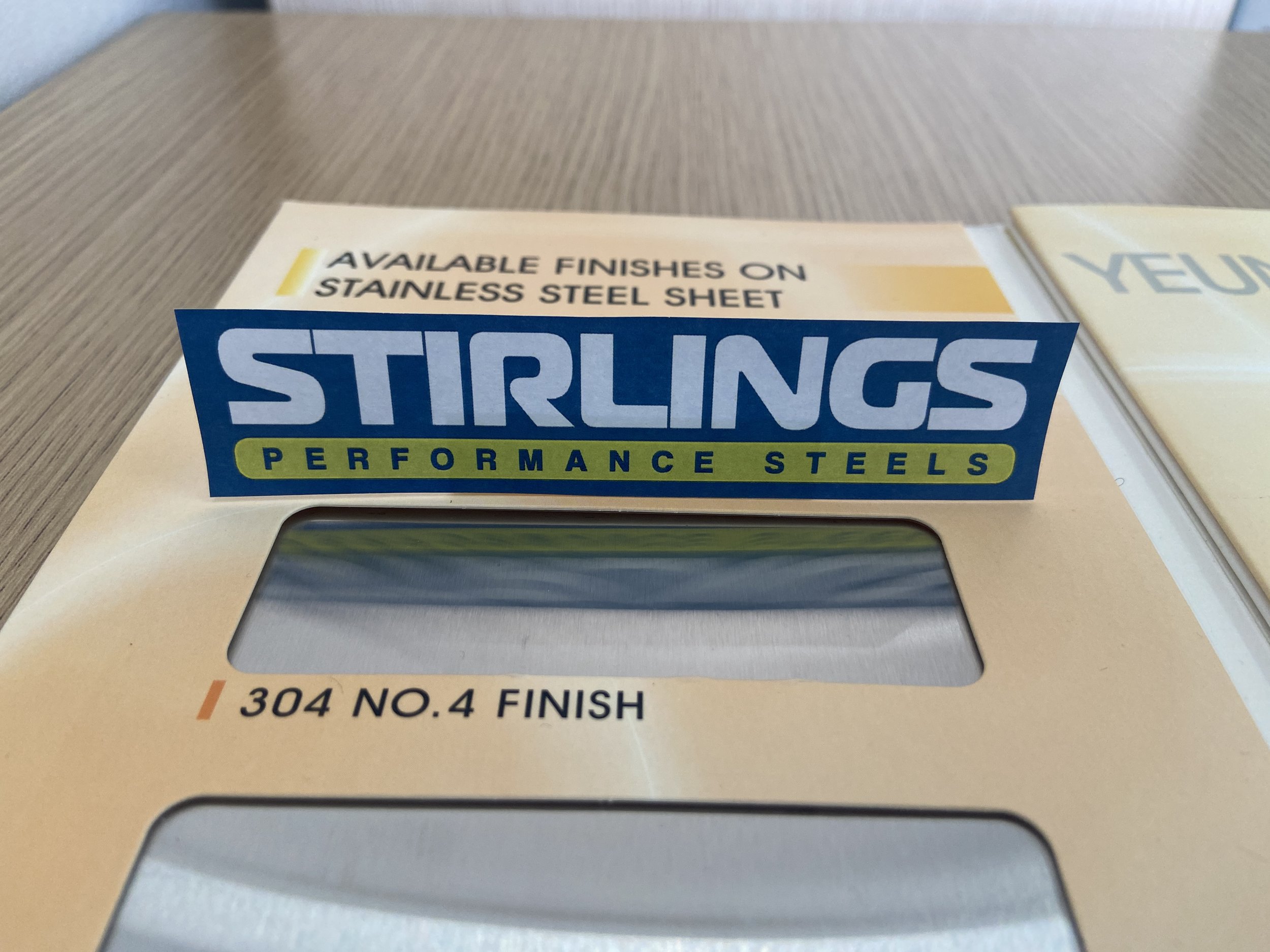

NO. 4 FINISH

A No. 4 Finish is achieved by polishing with abrasives of approximately 150-320 grit. It produces a brushed or fine-grain appearance, commonly used for kitchen appliances, countertops, and architectural applications. This is arguably the most common abraded finish, and is available for most flat products as well as Tubes. Profiles, Bars and Pipes can be locally polished to a No 4 finish.

Note that grit levels can vary markedly, so a common best practice is to specify an average roughness to ensure homogeneity across products.

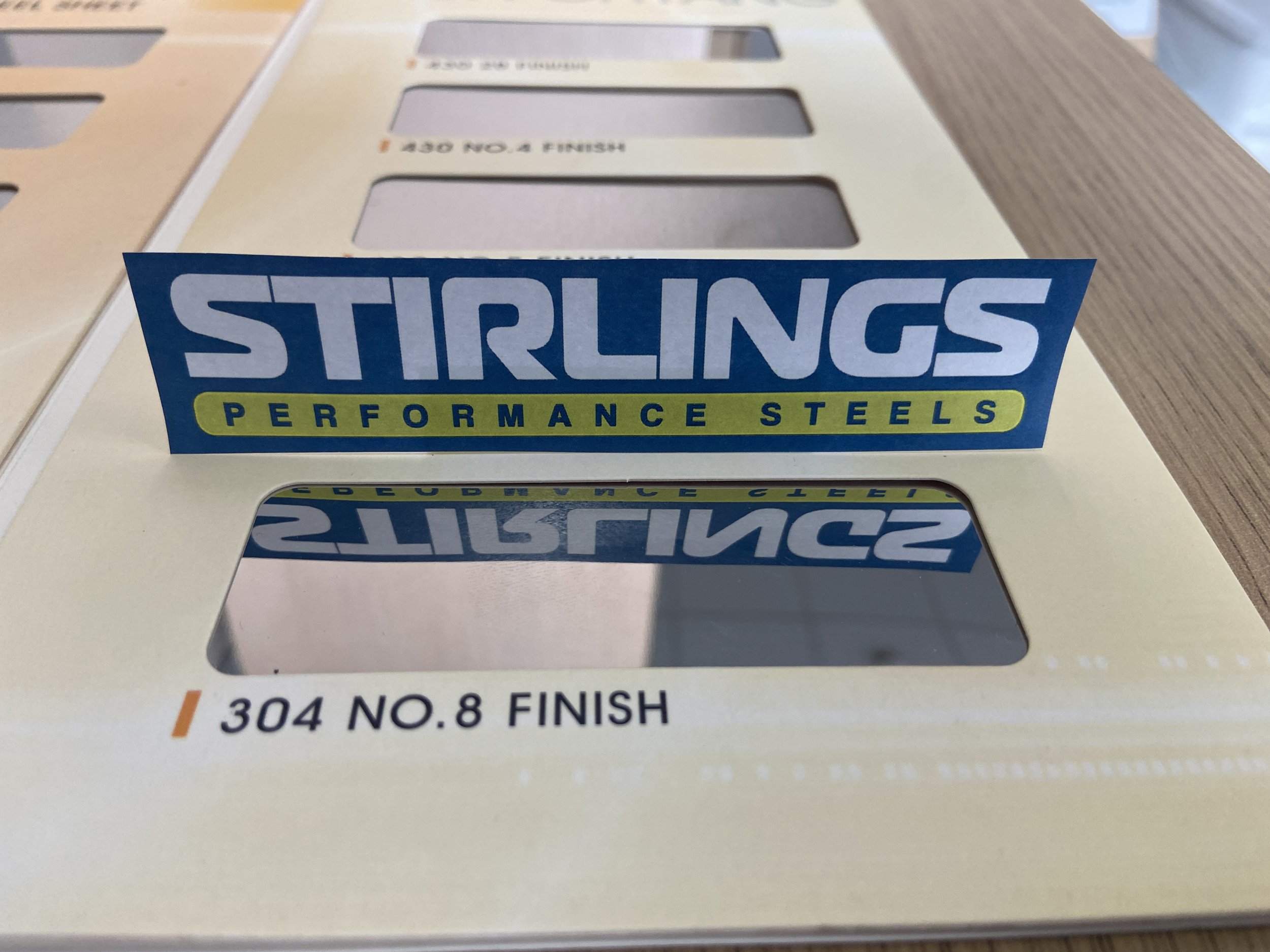

NO. 8 FINISH (MIRROR FINISH)

A No. 8 Finish is also known as a mirror finish. This finish offers maximum reflectivity and is free of any visible grain or texture. It's commonly used in decorative applications, such as mirrors, architectural panels, and ornamental pieces.

Other mechanically polished Stainless steel finishes:

NO. 3 FINISH

A No. 3 Finish is achieved by grinding with abrasives of approximately 100-120 grit. It produces a semi-polished surface, typically used for kitchenware such as utensils and countertops.

NO. 6 FINISH

A No. 6 Finish is a dull satin finish, achieved by polishing with abrasives between a No. 4 and a No. 8 (mirror) finish, often followed by a final pass with a fine abrasive or a soft buffing pad. This finish is less common than No. 4 and is typically used for specific aesthetic purposes or applications where a balance between reflectivity and texture is desired.

NO. 7 FINISH

A No. 7 Finish is semi-reflective achieved by buffing the metal but not to the extent needed for a full mirror-like No. 8 Finish. This finish is often used when a smooth yet not fully mirrored appearance is desired.

BEAD BLAST FINISH

A Bead Blast Finish is achieved by blasting the surface with fine glass beads or other abrasive materials under high pressure. This process results in a uniform, matte, and non-reflective surface, often used for its aesthetic appeal and to reduce glare in applications like architectural panels or industrial equipment.

Plate Finishes

Our Stainless steel Sheet and Plate is generally stocked in the following, although we can source most commercially available finishes:

NO. 1 FINISH

NO. 2B FINISH

NO. 4 FINISH

Square and Rectangular Tube Finishes

All the below finishes are available at Stirlings.

Unpolished

The raw finish as it comes from the manufacturing mill.

#180 Grit Polish

This is the most common finish on decorative tubing and is a brushed or satin finish. The finish is achieved by rotating the tube through a set of polishers.

#240, #320, #400 Grit Polish

Polished with higher grit numbers in the same process, resulting in a more satin finish.

#600 Grit Polish:

A highly reflective, mirror-like finish. This finish is achieved by first polishing the material (typically to a 320 grit) and further buffing the material to the desired, bright finish.

Annealed and Pickled

Mill Finish (Unpolished)

#320 Grit Polish

#600 Grit Polish

HiPol (#800 - #100 Grit Polish)

Tube & Pipe polishing service at Stirlings

We are able to polish Round Tube & Pipe up to a 114mm diameter in a variety of finishes with a choice between #180, #320, and #600 upon inspection.

For balustrade, furniture, architectural or marine, contact us for more information.

How we can help

As you can see, there are various methods (often used in sequence) to achieve a Stainless steel finish, resulting in many different end results for different uses. You don’t need to be an expert on all of these -- that’s our job! If you have a project in mind and are not sure which finish would be ideal, get in touch with our friendly team and we will help with everything you need to know about your specific use.

Know exactly what you’re looking for? Check out our range here, and place your order here, or check out our Online Superstore.

If you can’t find what you need, let us know here and we will source it!

A rhyme for your time:

Stainless has all sorts of finishes, from mirror to mill; find the right one for you, Stirlings makes it a thrill!

References